Ceramic Coating is a Durable, High-Heat Coating

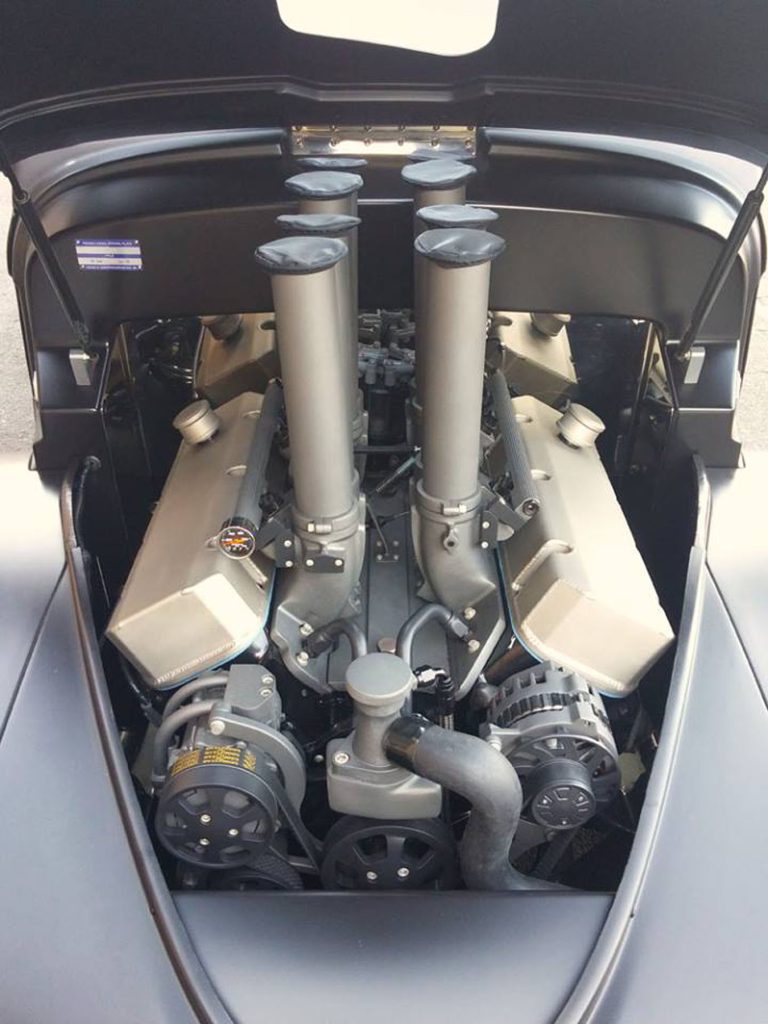

Ceramic coating, thermal barrier coating, heat transfer coating, and dry film lubrication coating are ideal for items that reach up to 2000 degrees and are always recommended on high-heat items such as exhaust manifolds, headers, and turbo housings.

How does ceramic benefit me?

High-temperature coatings are designed to improve the performance of exhaust systems. These coatings prevent corrosion, increase durability, and provide thermal insulation. Ceramic coating is an excellent thermal barrier. By doing so, ceramic coating reduces under-hood heat temperatures, thereby increasing horsepower.

The most advanced exhaust system coating available.

It is a durable ceramic-reinforced coating available in a variety of colors. When properly applied, it becomes the most effective thermal barrier coating available, increasing performance, while extending component life & has been tested to over 2000 degrees F without lifting, cracking, or flaking. Unlike header wraps, it does not hold potentially damaging heat & moisture around the part. Rather, the surface temperatures are actually reduced, extending the life of the part. When cured, a very effective corrosion-inhibiting film is formed that protects the part against oxidation and imparts excellent chemical resistance that further extends part life and enhances appearance.

Right now, we usually average about a 1-2 week turnaround on all ceramic parts, but it may be sooner or later, depending on workload.

If your items are currently chrome-plated plated additional charges will be applied.

The Cerakote ceramic coating colors we currently offer are:

- Blue Titanium

- Burnt Bronze

- Glacier Black

- Glacier Forge

- Glacier Silver

- Glacier Titanium

- Tungsten Grey

Looking for high-performance ceramic coatings?

Bonehead Performance special ceramic coatings are designed explicitly for thermal barrier protection, heat transfer, and dry film lubrication. Visit our High Performance Coatings page here.