We have hundreds of colors and combinations to choose from, such as clear coats, metallic finishes, candy colors, fluorescents, wrinkled finishes, flat through high gloss finishes, mirror finishes, and iridescent finishes. Be sure to browse through and experience a sample of our powder coating services, showcased in our gallery. If you have any questions, please don’t hesitate to contact us. We’ll be more than happy to explain the process to you and address all your concerns.

What is Powder Coating?

So, you’ve heard of it, but you’re not quite sure precisely what powder coating is. According to the Powder Coating Institute’s web page, “Powder coating is an advanced method of applying a decorative and protective finish to a wide range of materials and products that are used by both industries and consumers. The powder used in the process is a mixture of finely ground pigment particles and resin, which is sprayed onto the surface to be coated. The charged powder particles adhere to the electrically grounded surfaces until heated and fused into a smooth coating in a curing oven. The result is a uniform, durable, high-quality, and attractive finish.” There, so now you know! Or do you?

Why is Powder Coating Better?

More Durable – Powder coating provides consumers, businesses, and industries with one of the most economical, longest-lasting, and most color-durable finishes available. Powder-coated surfaces are more resistant to chipping, scratching, fading, and wearing than other finishes.

Color selection is virtually unlimited, with high- and low-gloss, metallic, and clear finishes available. Thanks to the UV resistance of many of the powders, colors stay bright and vibrant longer. Texture selections range from smooth surfaces to wrinkled or matte finishes, and rough textures designed to hide surface imperfections.

Protects the Environment – Powder coating is also highly protective of our environment. While liquid finishes contain solvents that contain volatile organic compounds (VOCs), powder coating contains no solvents and releases negligible amounts, if any, of VOCs into the atmosphere. Thus, there is no longer a need for finishers to purchase costly pollution-control equipment. In addition, most powder-coating overspray that does not adhere to the part can be collected and reused. Although this is not always practical for many of the low-volume users we service, this can virtually eliminate the waste commonly found in liquid finishing processes.

Saves Money – The elimination of VOCs and reduction of waste saves money and helps companies comply more easily and economically with the regulations of the U.S. Environmental Protection Agency. One of the significant factors in expanding the market for powder coating has been the implementation of stringent air pollution control legislation over the past 30 years.

Where is Powder Coating Used?

Appliances – The appliance industry benefits from powder coating on the front and side panels of ranges and refrigerators, washer tops and lids, dryer drums, air conditioner cabinets, water heaters, dishwasher racks, and the cavities of microwave ovens. Powder coating has also replaced porcelain enamel on many parts of washers and dryers.

Architecture/Building – The architectural and building market powder coats aluminum extrusions used on frames for windows and doors and modular furniture. Many highway and building projects utilize powder coating on light poles, guardrails, signs, posts, and fencing.

Automotive – Henry Ford once said, “You can have a Model-T in any color you want. So long as it’s black.” For an industry once focused primarily on manufacturers’ needs, powder coating is transforming the automotive industry, offering faster production times, lower operating costs, and irresistible value propositions for consumers. For years, conventional liquid coatings were the standard for the automotive industry. However, these coatings can emit hazardous VOCs during their application stage. Powder coatings eliminate most environmental concerns and the need for costly waste disposal systems. Because powder does not run or drip, the result is a uniform, superior-quality finish.

The conversion from liquid to powder clear coats for auto body exteriors is progressing rapidly. Powder topcoats resist acid rain, the sun’s ultraviolet rays, and road and weather damage, helping cars retain their “showroom look” much longer and improving their resale value. BMW and

Volvo is using it on their new model cars, and GM, Ford, and Chrysler have formed a consortium to test this technique on their production lines.

Powder coating has made substantial inroads as a primer for car, van, and pickup truck bodies in the United States. Auto body primers in colors will be following.

There is enormous market potential for high-heat-resistant powder coatings on aftermarket mufflers, which resist corrosion, protect against nicks, and prolong the muffler’s life. Some companies are already applying heat-resistant powder to aftermarket mufflers, and the new-car market is thought to be two or three years away.

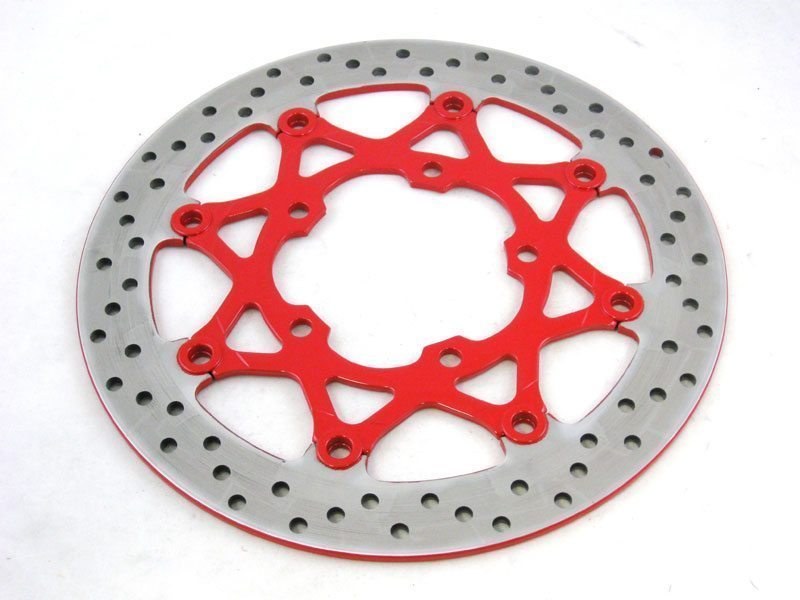

Powder coating is also applied to wheels, grilles, bumpers, door handles, roof racks, and exterior and interior trim. “Under the hood” uses include oil and fuel filters, brake pads, engine block casings, suspension components and radiators. Pickup truck and SUV owners can purchase powder coated side steps, bed rails, luggage racks and toolboxes as dealership add-ons or in aftermarket stores and catalogs.

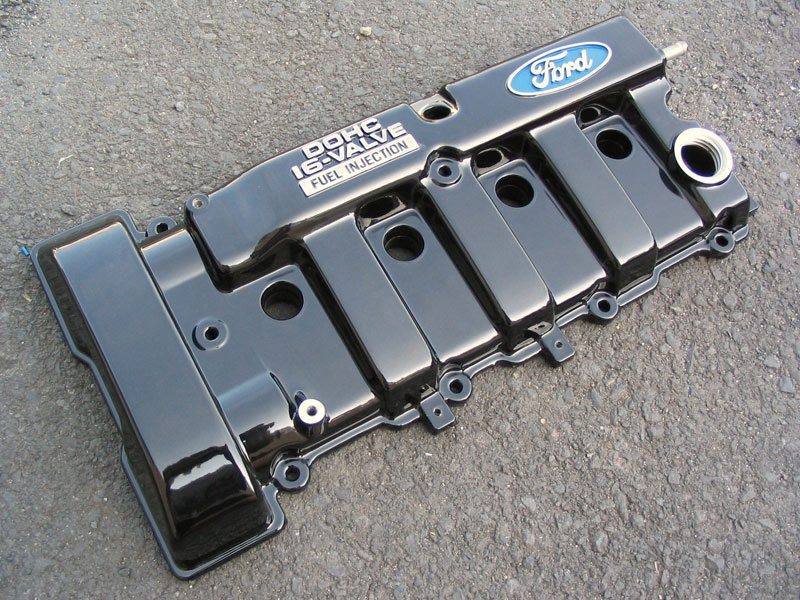

Performance car owners can find powder coated special suspension units, carburetor parts and valve covers, plus flashy rear-view mirror mounts and other exterior adornments.

Everyday Products – There are also innumerable everyday uses for powder coated products such as lighting fixtures, antennas, and electrical components. Farmers have powder coated tractors and farm equipment. Fitness buffs use golf clubs and golf carts, ski poles and bindings, snowmobiles, bicycles, and exercise equipment that are powder coated. Shop owners have powder coated display racks, shelves, store fixtures, and vending machines. Office workers use metal furniture, computer cabinets, mechanical pencils and pens, thumbtacks, and other desk accessories that are powder coated. Parents have powder coated baby strollers, cribs, metal toys, and wagons. And homeowners have lawn mowers, snow blowers, barbecue grills, patio furniture, garden tools, electronic components, bathroom scales, tool boxes, and fire extinguishers which benefit from a powder coated finish. The powder coating boom has just begun, expect more exciting uses in the near future.

What is the turnaround time?

This is the most famous question we hear. It is very hard to estimate turn around time if you are shipping in items to be coated. The day you ship them to us may be a 3-4 day turnaround time but by the time they come in to our shop it may be an 8-10 day turnaround time. Times change by the hour at our shop so this is a very hard question to answer. We work very hard to get your items back to you asap but sometimes there may be a delay depending on workload. Winter time is our busiest time because everyone takes apart their bikes and cars to get items coated. In most cases we don’t like to have customer items at our shop longer than 2 weeks but is usually sooner. Winter time may be longer than this as it gets very busy. For rush jobs we charge an extra 50%. In doing this we stop everyone else’s work to work on your items.

How do I send something in to be coated? Go to this page.

NOTE: YOUR PARTS MUST BE COMPLETELY DISASSEMBLED OR ADDITIONAL CHARGES WILL BE APPLIED. ALL BUSHINGS, BEARINGS, SEALS, GASKETS ETC. MUST BE TAKEN OFF OR PRESSED OUT PRIOR TO SENDING ITEMS IN TO BE COATED. See full details here.